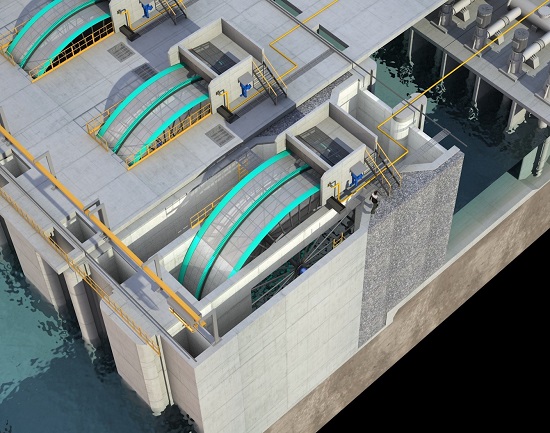

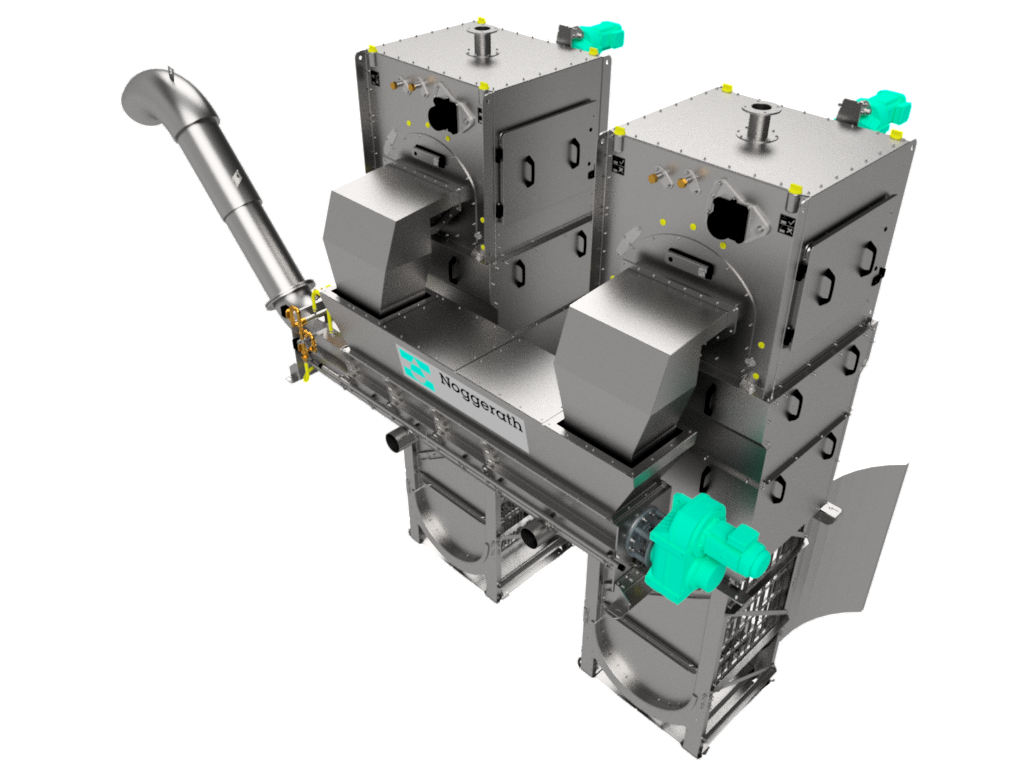

Before water can be used for the processes, it needs to be cleared from pollutants and suspended solids for an optimized heat rate, lowest downtime risks and less or no backflushing of debris filters. Always aiming for the highest energy-efficiency of your plant!

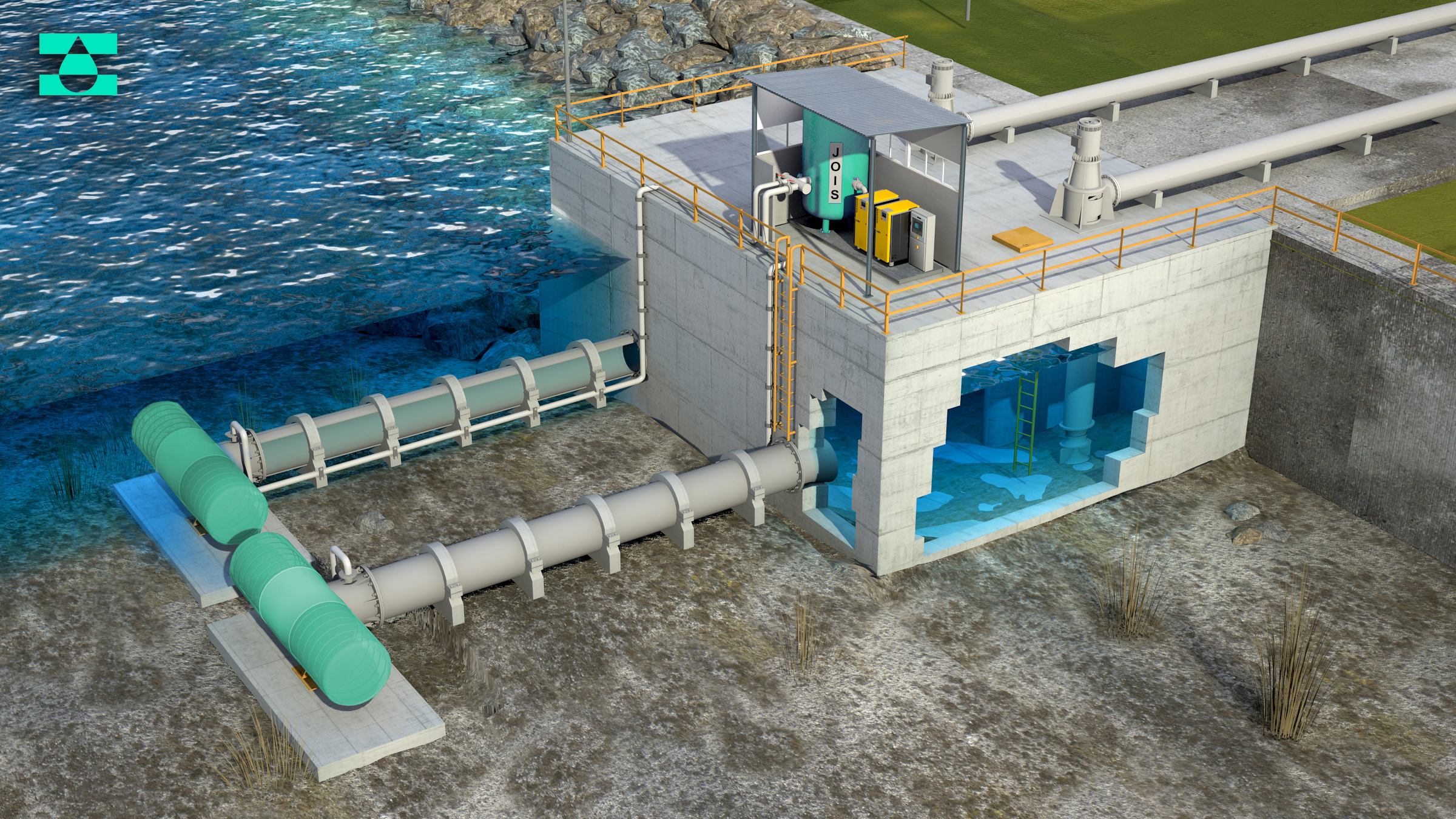

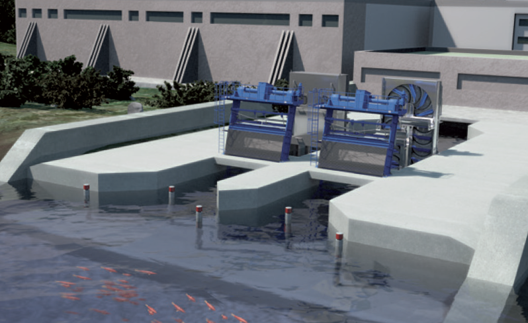

In the case of cooling, in order to prevent damage to pumps and heat exchangers, the sea or river water required has to be cleared of debris, eg, sea weed, jelly fish, plastic, sand, etc. This is where our zero-carry-over bar and mesh screening machines come into their best application.