Geiger®

Cable-Operated Grab Cleaner /

Bar Screens Raking Machines /

Trash Raking

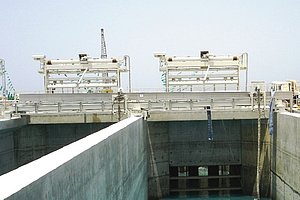

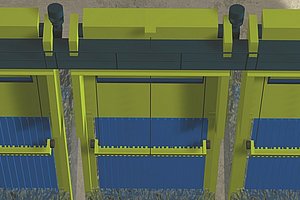

Cable-Operated Grab Cleaners/Bar Screens are typically installed in water intake systems as front-end coarse screens or trash racks. Depending on technical requirements, there are stationary and traversing versions available, to minimize costs on multi-channel intake designs at optimized reliability.

Unique Features

- Available as stationary or traversing/movable machines for multiple channels- one grab cleaner for three or more channels

- Intelligent cleaning technique

- Highly reliable grabbing and removal of bulky debris

- High loading capacity of the grab cleaner

- Different speeds for the cleaner carriage during the descent and cleaning cycle

- The cleaning cycle can be started from any grab cleaner position

- Exact limitation of the lifting movement

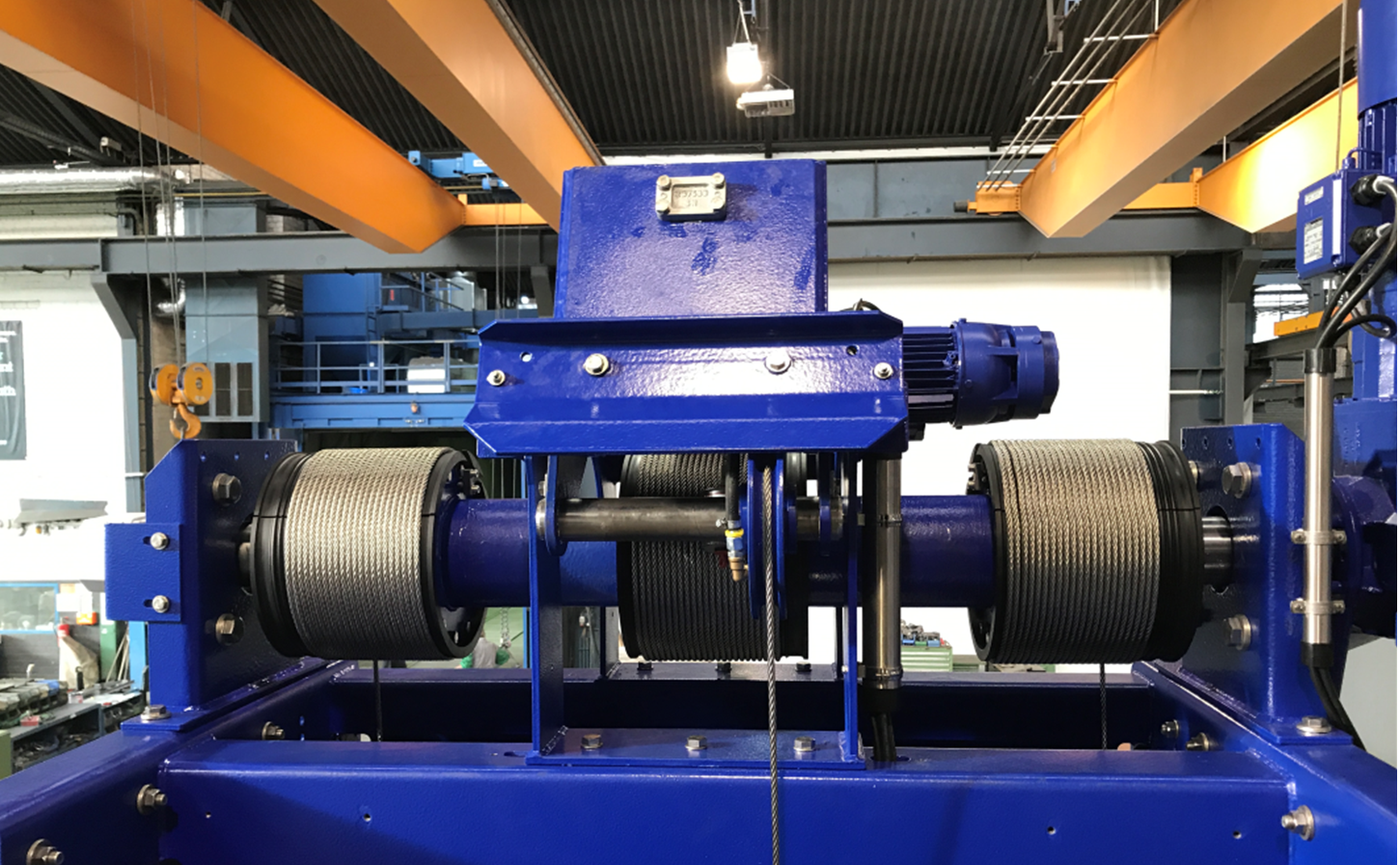

- Fully automated cleaning operation with slack rope control (for 3-rope device).

- Adaptable: Different speeds for the cleaner carriage during the descent and cleaning cycle.

- The cleaning cycle can be started from any grab cleaner position, due to the slack-rope control

- Polyamid hose drums to minimize wear and tear and for longest, easiest service life (awarded by the Federal German State of Baden-Württemberg)