Service

Reliable Technologies powered by our brands Passavant®, Geiger®, Noggerath®

Everything for smooth operation and fast supply.

more_vert

Service

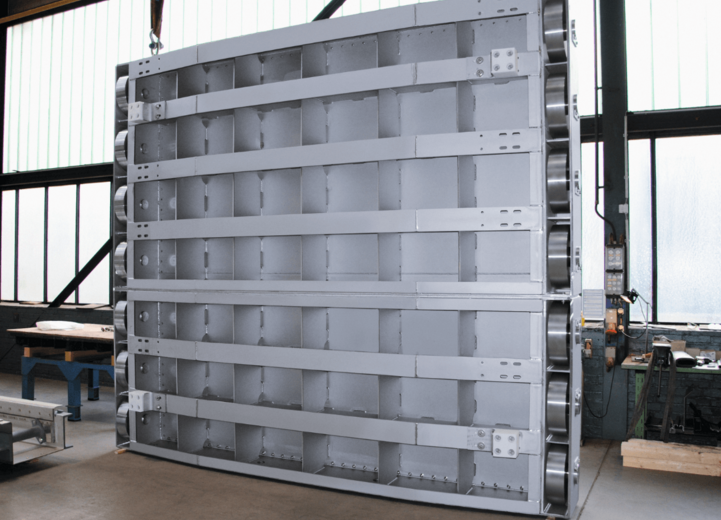

Assembly / commissioning / repairs of machines and plants

- Spare and wear parts supply from our own production

- Consulting and customer service

- Maintenance and refurbishment

- Maintenance work / preventive maintenance

- Retro-fitting of machines (also from other manufacturers)

- Modernization and expansion for operational safety of automation and plant networks

- Remote maintenance / access to machines and plants via secure VPN connection