As the last cleaning stage for water intakes, finest screening/filtration is of particular importance to protect downstream equipment such as pumps and condensers reliably against clogging. Passavant-Geiger Centre-Flow (In-to-Out) Travelling Band Screens are the well proven design variant of conventional Travelling Band Screens for minimized life cycle costs and the most efficient extraction of fine debris. Many of our machines have been running successfully at sites for over 40 years on seawater and river water applications.

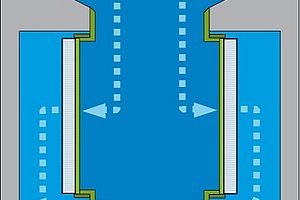

Compared to Dual-Flow band screens (out-to-in flow pattern), our Centre-Flow band screens avoid the accumulation of debris under the machines, which would be difficult to remove from the bottom of a channel.

The spraying of the panels takes place automatically at the upper part and is following the natural gravity direction, thus minimizing water leakages to the operational deck.

Depending on site requirements, the mesh panels are either flat or roof/halfround-shaped. With roof or halfround-shaped mesh panels a higher efficiency of the machine size can be achieved and bigger particles cannot drop back so easily. Special features are the maintenance-free side bar chains to guide the mesh panels, a highly efficient, scale- like sealing between the screening elements, chain and curved guidings as well as the chain track on the clean water side. The adjustable band speed allows optimum adaptation of the flow rate and screen washing. Excellent cleaning of the mesh panels is achieved by means of an intense washing; the wash water system is adjustable and controllable via local/remote control. A nozzle cleaning device with automatic control is available as an option. The chain tension can be adjusted from the operating floor level. For sea water applications, the chains and chain guidings should be protected against corrosion by means of efficient special anodes forming part of our long proven and project-tailored cathodic corrosion protection system with impressed current.

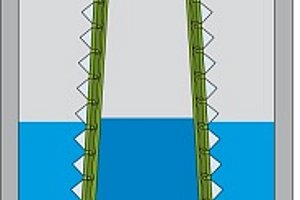

Travelling Band Screens/Traveling Water Screens can also be equipped with fish buckets to help protect aquatic life. Our travelling water screens with the patented fish bucket system are EPA 316b-compliant as the best available technology (BAT) to reduce impingement. The fish are gently removed separately from the debris by lower pressure jets and from a lower height into a separate trough for the return into the water bodies. Due to the special coating of our fish buckets and a special hydraulic form, fish are prevented from sticking to the metal as well as from jumping out of the buckets during the uplift.

Fish return troughs and debris troughs can be independent or combined based on customers’ requirements