Noggerath®

Rotary Drum Screen

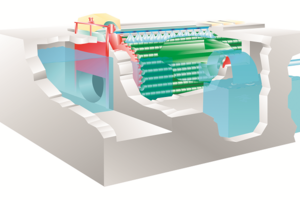

RSH-M / RSH-MG

The versatile micro screening drum system – convincing through efficiency and economy. The RSH-MG-D product variant satisfies even the highest water treatment requirements.

Unique Features

- High flow rate due to curved screen panels

- Low pressure drop

- Direct drive via a gear wheel

- Blades mounted in the screen baskets prevent screenings from falling back into the raw water (RSH-M)

- Integrated emergency overflow (RSH-MG)

Insights

Technical data

The raw water passes through the screen drum cage from the inside to the outside, leaving solid particles on theinner surface of the screen. The resulting buildup on the screen surface blinds the mesh openings causing a pressure loss across the screen. When a defined difference is detected between the upstream and downstream water the drum begins to rotate. During the rotating movement, the screen mesh is backwashed with an external sprayingdevice. This spraying device is located in the apex of the micro screening machine. The cleaning of the screen panels improves the filtration performance and reduces the water level differential, resulting in the drum stopping its rotation.

The cleaning water and screenings are directed out of the drum via the internal launder channel, a screenings press or a spiral conveyor.