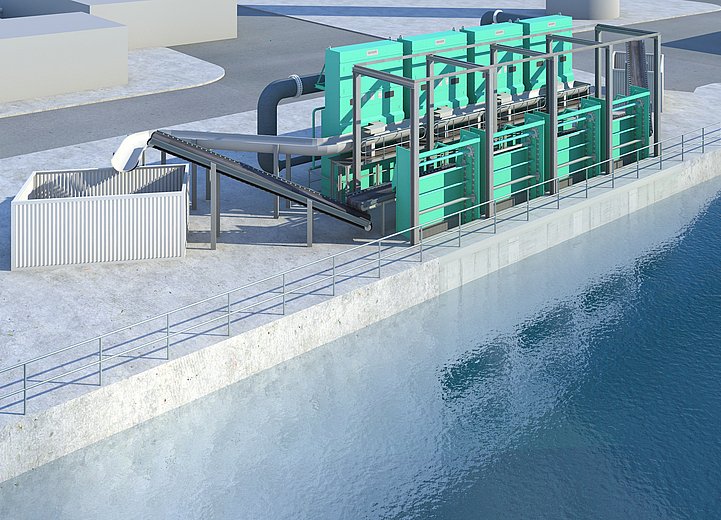

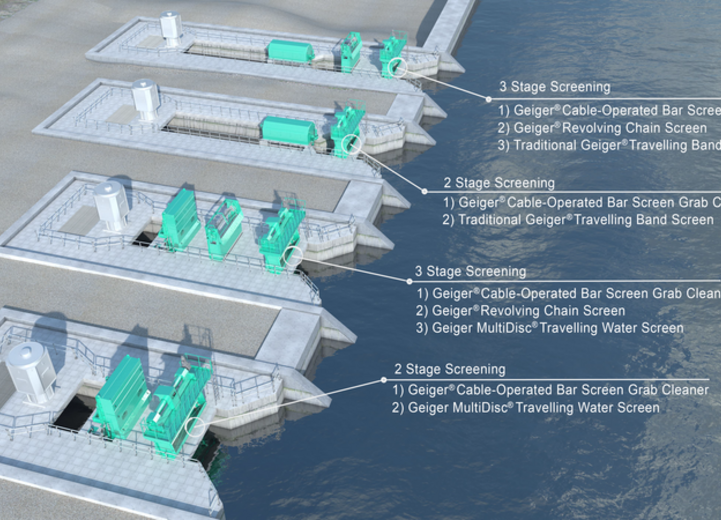

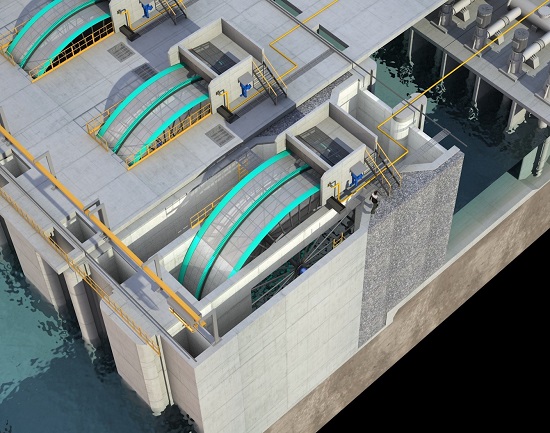

Looking for a completely new concept and in view of modern requirements, we developed the renowned Geiger® MultiDisc® screen which has been successfully

installed hundreds of times worldwide.

The advantages of Geiger® MultiDisc® are:

- Its compact design allowing significant cost reductions in civil structure volume

- Its fast and simple plug-in installation

- Its low operating costs:

- a) Only one maintenance-friendly bar chain

- b) Easy maintenance; mesh panels can be changed at operator’s floor level (no need for channel dewatering)

- Lower head loss: water only passes through the screen once

- Optional fish protection (EPA clean Water act – section 316b pre-approved technology) – intensive and efficient cleaning of the mesh panels

- Zero carry-over of debris to the clean water side

- Shorter channels

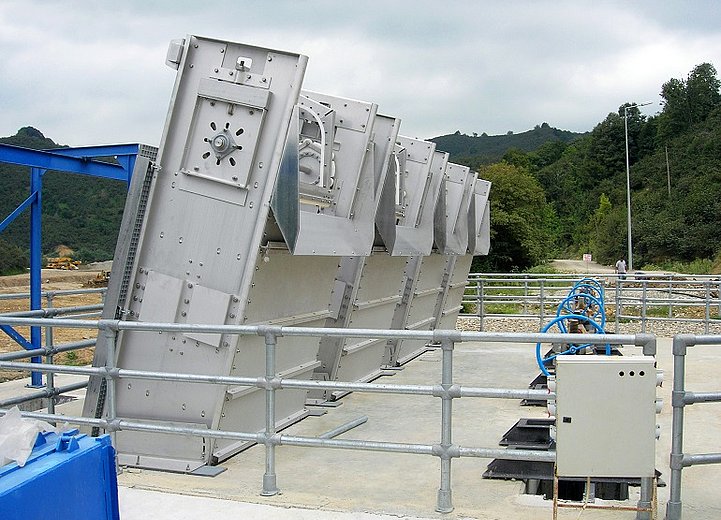

Executed projects have proven that the Geiger® Multi-Disc® can be retrofitted into existing water intake structures within 24 hours, including removal of the old through-

flow band screen, installation of the Geiger® MultiDisc® and commissioning. Both the Geiger® MultiDisc® and our Travelling Band screens are available project-specifically with plastic or stainless steel mesh ranging from 0.2 – 10 mm. Furthermore, for special applications we offer micro drum screens with a mesh size down to 15 microns.