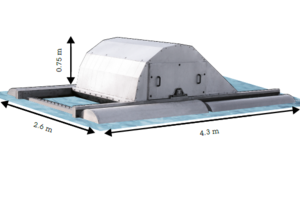

Passavant® Mammutrotor Lago

Specially developed for municipal and industrial pond-style wastewater treatment plants or small conventional wastewater treatment plants with circulation flow: The Mammutrotor® Lago convinces with an innovative drive concept and low maintenance requirements.

Unique Features

- Constant oxygen input and efficiency over entire life cycle

- No negative influence on the oxygen input in case of varying wastewater characteristics – α-factor is close to 1

- Embedded guide baffle for high energy efficiency and direct flow to deeper water layers

- Innovative drive concept without coupling

- Many options available for addition