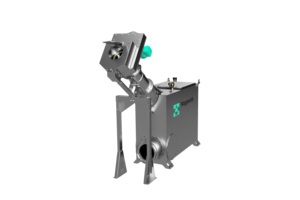

Noggerath®

Spiral Sieve

NSI-T / NSI-T-RED

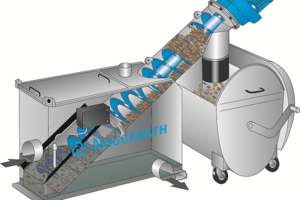

Fine screening of wastewater in a tank with a perforated or wedgewire screen, including conveyance of screenings, dewatering, compacting and discharge.

Equipment for the fine screening of wastewater in inlet has been part of the standard range of the brand Noggerath of Aqseptence Group since 1988.

Our compact and robust spiral sieves are ranked among the best machines

of their kind in the world.

Unique Features

- Fine screening and dewatering in one unit

- Simple retrofitting, no bed drop required

- Complete hygienic stainless steel encapsulation

- High operational reliability: – no blockages or pigtailing – no pressing of screenings through the sieve surface

- No service water required in the pressing zone