Situation

Passavant® Aqualogic®

Winterhausen, Germany

Aqualogic® Control System – Increasing Process Efficiency - Wastewater Treatment Plant Winterhausen (95,000 PE)

More than 50% of the energy consumed by water treatment plants is used to generate compressed air for the biological purification process. The aeration system is usually operated with a constant pressure in the collector pipe. A possible approach to save energy during this process is to adjust the pressure to the actual requirements. During a period of low load, a lower pressure is sufficient to convey the amount of air necessary for the decomposition processes.

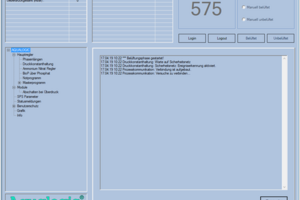

The Aqualogic® control system offers this option with the Enerlogic® pressure control. Based on Fuzzy Logic, the optimal pressure is calculated based on the ammonium load and the compressor power is automatically adjusted.

Challenge

Optimizing the control of the aeration system using the Aqualogic® control system.

The biological treatment stage of the water treatment plant in Winterhausen consists of two parallel aeration lines. The compressed air is generated by two turbo compressors and distributed to the lines by four diaphragm control valves.

Solution

With the Aqualogic® control system, the valve’s opening degree is calculated and controlled depending on the current load. In parallel, the Enerlogic® pressure control module is started. This module adjusts the pressure in the system in relation to the load and controls the power of the turbo compressors accordingly. There is an interaction between the optimal opening degree of the valve, the current necessary pressure, and the corresponding compressor power in a single controller.

In addition, operation of the two lines is alternated. This may cause the turbo compressors to run for a longer time, but they also run more efficiently.

Results

Since the installation of the Aqualogic® control system, the aeration system at the water treatment plant in Winterhausen has been controlled in a safe and stable manner.

The Aqualogic® control system’s efficient control of the turbo compressors has reduced current peaks. The alternating operating mode reduces the number of starts and stops of the turbo compressors, leading to energy savings.

The customer is very satisfied. The operating personnel found the settings options directly on the Aqualogic® control system to be particularly convenient.

Benefits

- Efficient control of the entire compressed air supply for the biological process (valve, pressure, and compressors) in a single system based on Fuzzy Logic

- Optimization of the biological purification process and energy savings

- Various settings options directly on the Aqualogic® controller

- Aqualogic® can be successfully operated regardless of the manufacturer of the measuring technology or installed aerator, and can be used with the existing programmable logic controller

- Option of a multi-month test of the Aqualogic® control system

Technical Data

Passavant® Aqualogic®

(energy efficient control)

- Variable pressure control