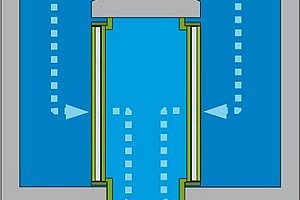

Geiger® Dual-Flow (Out-to-In-Flow) Travelling Band Screens

For decades, Geiger® Dual-Flow (Out-to-In-Flow) Travelling Band Screens, have been operating successfully in the water intake systems of power stations, petrochemical plants and sea water desalination plants, steel works and other industrial plants all over the world.

Unique Features

- Possible installation in self-supporting frame

- High throughput and functional reliability

- High quality Geiger® chains with polyamide rollers and option for cathodic corrosion protection by impressed current for seawater applications