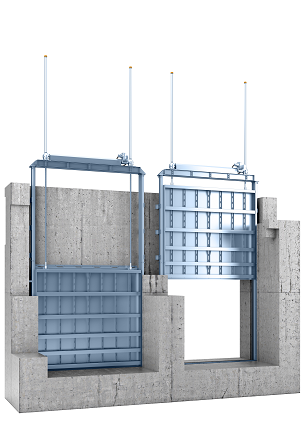

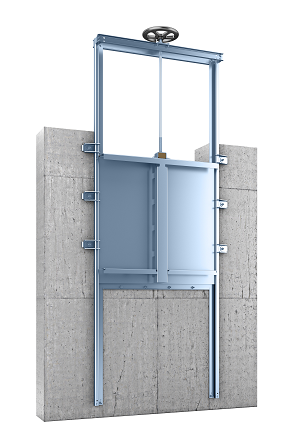

With our brands Geiger® & Passavant® for open channel/onshore intakes and Johnson Screens submerged passive intakes/JOIS™ we develop and produce solutions for the intake of sea and brackish raw water including bar screening and trash raking machines, as well as mesh/travelling band screens/traveling water screens for the filtration of seawater, mainly made in Germany and the US for installations around the globe.

We have been providing machines for seawater intake systems with zero-carry-over and large-debris-handling (including jellyfish) for decades.

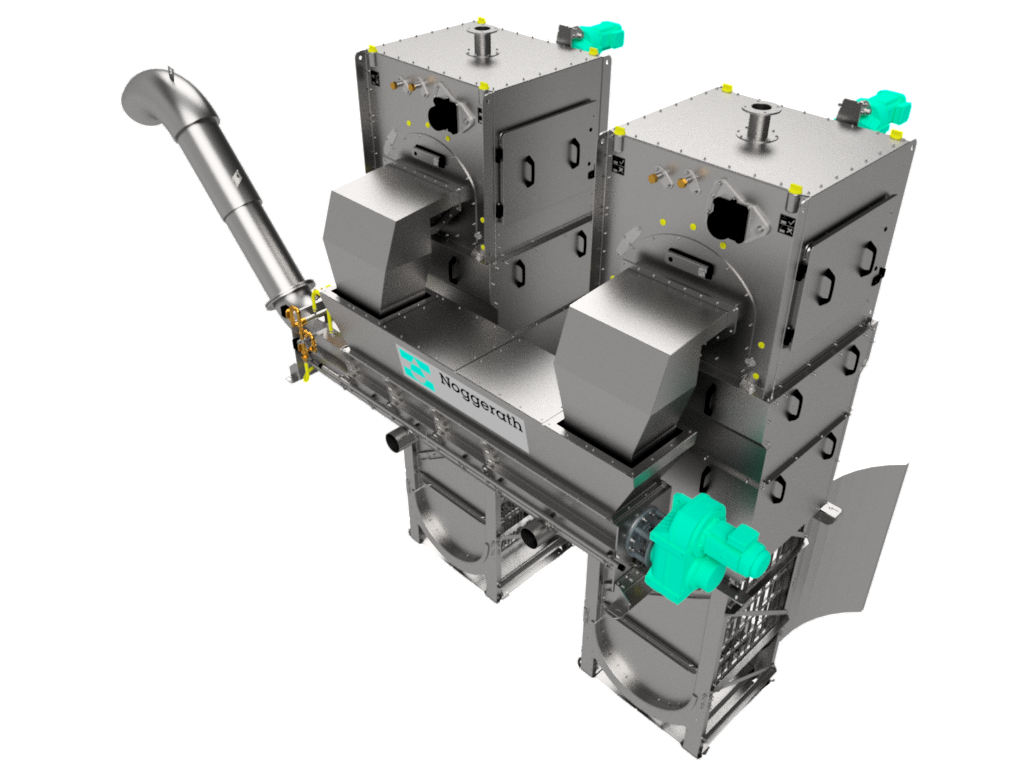

We supply and design-build made-to-measure automated screening machines for the filtration of debris at seawater inlets for thermal power plants (nuclear-, gas- and coal-fired power plants), desalination plants, and industrial- and potable water systems. The aim is to protect pumps and other downstream equipment from the carry-over of debris. More than 1000 seawater intakes worldwide (Greenfield (new) and Brownfield (replacement/spare parts)) are equipped with our machines. Our references on seawater intake screening plants have proven lifetimes of over 30 years.

To protect machinery from corrosion caused by saline water in order to increase its lifetime, we advise the additional use of Geiger® Cathodic Corrosion Protection systems using either impressed current (ICCP system, made in-house) or sacrificial anodes, in combination with 316L or Duplex materials.

We have been providing state-of-the art fish and eel protection technology according to the EU-Habitat guideline, and to the EPA’s Clean Water Act 316b, for decades.