Geiger® 316b Screens

The 316(b) rule of the Environmental Protection Agency (EPA) forces US plant owners to refurbish their water intakes with more fish friendly screening technologies. Geiger can offer solutions for best possible fish protection in compliance with EPA 316(b). Offshore / deep water intakes equipped with Johnson® Passive Screens ensure fine screening with least disturbance of aquatic life. Open channel water intakes equipped with Geiger MultiDisc® fine screens provide gentle uplift and return of the fish from the intake channel back to their natural water body.

Unique Features

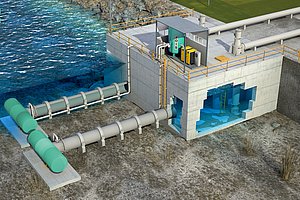

Johnson® Offshore Intake Systems

- Passive intake screens are slotted and cylindrical shaped without any moving parts

- Design slot velocity should not exceed 0.5 feet per second (0.15 m/s) to minimize entrainment

- Unique screen design ensures very low and homogeneous velocity distribution as well as minimized clogging risk

- Suction effects are avoided so there is virtually no influence on aquatic life.

Increased intake capacity up to 40% thanks to newly developed Max-FlowTM Passive Intake Screen

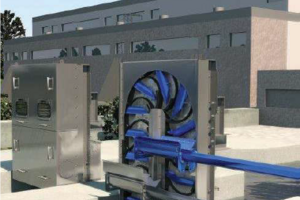

Geiger MultiDisc®Screens

- This advanced type of travelling screens is certified as “best technology available” to minimize impingement and enhance survival rates of aquatic life.

- Specially designed fish buckets on each screen panel ensure gentle uplift and discharge of the fish back to their natural water body

- Separate handling of fish return and screening discharge possible; low pressure spray system for fish return, high pressure spray system for best cleaning performance

- Screen design features significant advantages over conventional travelling screens such as zero carry-over risk, compact and fast installation, reduced maintenance demand