Solution

Passavant® Aqualogic®

Bickenbach, Germany

Modern control and precipitant dosing technology - treatment performance and energy efficiency at the highest level. One of the first advanced WWTP (4th-stage) in Hesse based on granulated activated carbon adsorption, cloth filter and ozonation.

Situation

The Wastewater Treatment Plant Bickenbach of the Bickenbach-Seenheim-Jugenheim Wastewater Association was originally put into operation in 1967. At the beginning of the 1990s, it was expanded to 32,000 population equivalents.

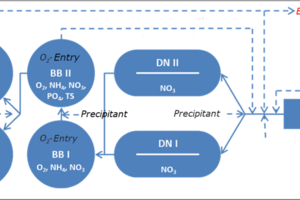

Wastewater treatment takes place in two parallel lines, each with an upstream denitrification stage and two intermittently aerated nitrification tanks that are flowed through one after the other. Control is via various ammonium and nitrate probes as well as oxygen, orthophosphate and inflow measurements.

The process water is treated in a deammonification stage and then fed back into the wastewater treatment system. The plant is being extended in 2023 with advanced treatment to retain micro pollutants.

The wastewater treatment plant has sludge digestion and was one of the first plants in Hesse to be expanded by a fourth purification stage (cloth filter, ozonation, granulated activated carbon adsorption) since 2021.

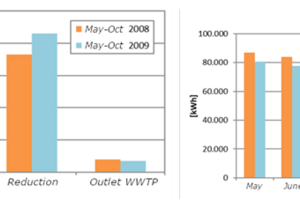

Although the wastewater treatment plant met the legal requirements very reliably, the energy used for this was at a high level of >40 kWh/ PE/a.

The Aqualogic® controller system is already in operation and uses the same input variables as the previous controller to control the biological processes. Installation was straightforward on the existing SCADA-system, and communication with the PLC is via OPC. Due to the use of fuzzy logic, the control is now much more efficient and also resulted in better sludge characteristics.

In addition to optimising the control technology, the phosphate elimination was also improved by installing a TSM-Module® in the inlet channel. This results in significantly better mixing in of the precipitant and therefore improved and more efficient P-elimination.

Results:

Controlling the processes related to biology with Aqualogic® led to a number of significant improvements:

- Significant reduction in the Nanorg outflow load despite a significantly higher Nanorg inflow

- Significant improvement in sludge index and visibility depth

- Reduction of the total energy consumption of the wastewater treatment plant by 10 %

- Significant improvement in phosphate elimination efficiency

- Significant savings in precipitant

Advantages

- Efficient and reliable control of the biological purification process based on fuzzy logic

- Significant energy and precipitant savings with simultaneous improvement of the discharge values

- Flexible - can be adapted to local conditions

- Various straightforward setting options are possible directly from the Aqualogic® controller

- Aqualogic® is flexible when it comes to selecting the measurement technology and aerator manufacturer as well as the programmable logic controller

Summary

Even if wastewater treatment plants reliably meet the legal requirements, it is worth constantly monitoring and questioning the own operation and considering the use of new, more efficient technologies.

As shown, in the case of the Bickenbach wastewater treatment plant, the use of modern control and precipitant dosing technology enabled a significant increase in treatment performance with a simultaneous reduction in energy and precipitant procurement costs. Ultimately, this benefits not only the operators, but also the public and the environment.

Technical Data

Passavant® Aqualogic®

(energy efficient control via ammonium nitrate for two activated sludge lines)

Enerlogic® module - load/ammonium dependent oxygen target value specification

Excess/return sludge control module

Recirculation control module

Process water module Load-dependent bypass of the preliminary treatment module

Phosphate precipitation module

TSM-Module®